Using AI to analyze worker activity in manufacturing shop floor

(Published 16 August, 2021)

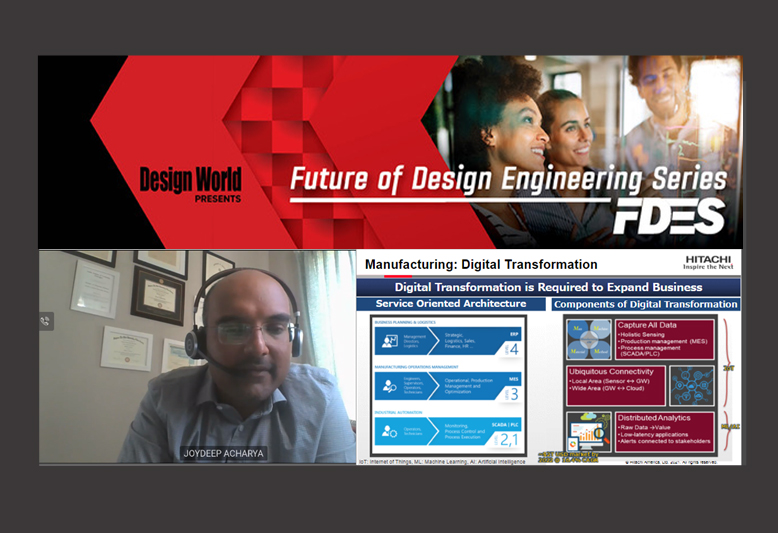

At Hitachi America R&D, our goal is to discover new answers to society’s challenges. We recognize that the internet of things (IoT) edge and artificial intelligence (AI) are critical to every industrial IoT solution. These solutions have the potential to solve many problems facing societies today.

Artificial intelligence (AI) embedded in the IoT edge has the potential to transform manufacturing by improving shop floor process such as production, maintenance and quality. However, industrial datasets are notoriously difficult to extract in real time, making it very difficult for manufacturers to realize this potential.

At a recent online webinar that was organized by Research & Development World of WTWH Media, as part of their Future of Design Engineering Series, Joydeep Acharya, Ph.D., Sr. Manager of Hitachi America R&D presented “Using AI to analyze worker activity in manufacturing shop floor”.

For various field applications such as manufacturing, workers contribute to maximum fluctuations in processes such as production and quality. It is hard to quantify and capture worker performance in a scalable way. Hence there is a need for developing AI-based sensor technology that can automatically collect data about manual processes and provide insights for operators, without requiring intervening human supervision.

To address this problem, Hitachi America R&D has developed vision-based analytics solutions. First the manufacturing shop floor is instrumented with RGB and depth sensors such as LiDAR to capture rich datasets pertaining to worker movement. Then a two stage AI algorithm is used. In the first stage the raw vision data is used to derive human pose information given in terms of keypoint joints. In the second stage the keypoint information over several frames is passed through a deep neural network to infer human activity patterns. This information can be used to monitor important KPIs that machines can’t directly yield such as process cycle time.

This talk highlighted how vision-based AI can be used to analyze worker activity in the shop floor. The talk was followed by a lively Q&A session where a wide range of issues from technical challenges to privacy concerns to Hitachi’s commercial offerings were discussed. Watch On-demand now.

For more information regarding how to connect the data to an AI application in a secure, reliable and available way, please contact us at https://www.hitachi.us/rd/contact-us/.