Reinventing the Manufacturing Value Chain

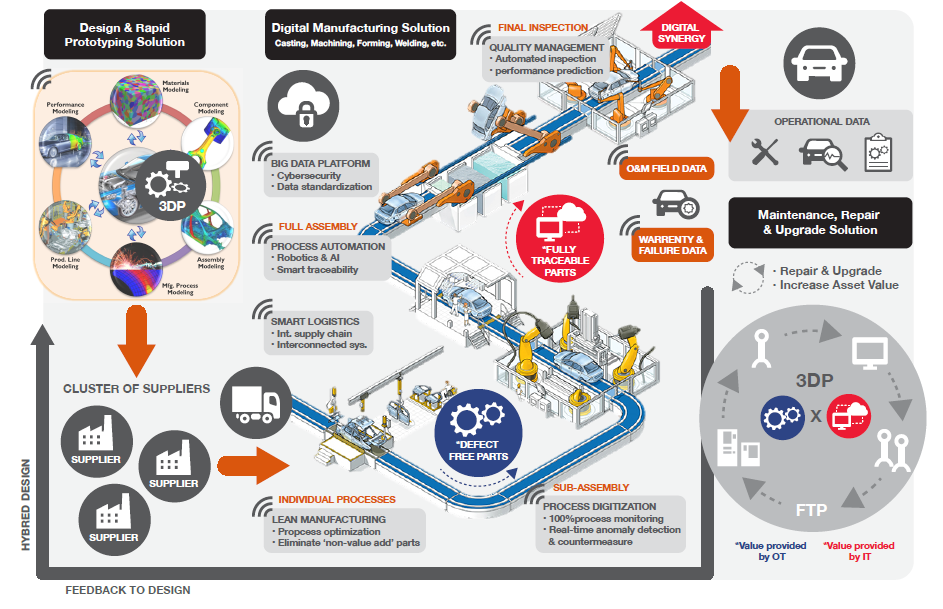

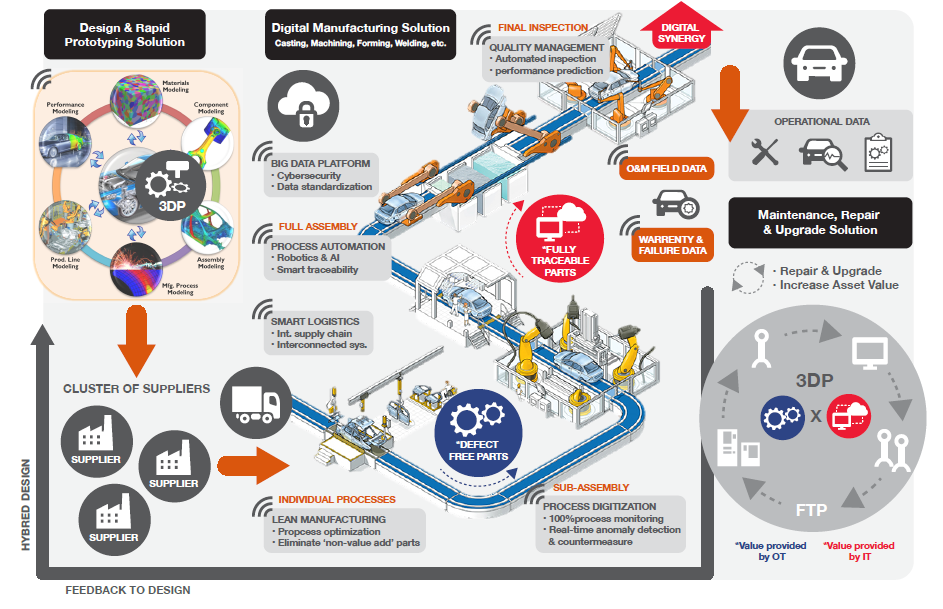

A thorough understanding of the manufacturing process is key to keeping production quality up and costs down. That’s why today’s manufacturers are turning to end-to-end value chain solutions to improve and modernize product design, prototyping, manufacturing, and maintenance, repair and update (MRU) capabilities.

The Hitachi America Research and Development Division (R&D) is tapping into Hitachi’s extensive IT and operational technology (OT) experience to co-create value chain solutions with our customers. Our end-to-end manufacturing value chain solutions focus on rapid prototyping, smart manufacturing and MRU development. The solutions apply advanced technology to address the dynamic changes affecting manufacturing industries globally.

Our solutions include:

- Rapid prototyping: Hitachi helps customers achieve the best design and prototyping solutions. We use advanced computational tools; our profound knowledge of materials, process, property and performance from static to dynamic; and field-proven experience in virtual manufacturing to accelerate design and production. Our prototyping solutions use the latest augmented reality/virtual reality and three-dimensional printing (3DP)/additive manufacturing technology to streamline the prototyping process and keep costs down.

- Production process innovation: We have developed and implemented innovative new technologies to support production. Our solutions include basic incoming raw material analysis, failure root cause analysis and manufacturing process innovation. For example, some of our process innovations include digital casting, high-speed precision machining, cutting-edge fluid spray technology for machining, high-accuracy bending and forming, and high-speed fusion and solid-state welding. Product quality is assured with destructive and non-destructive testing and inspection, and intelligent production traceability systems help optimize the supply chain.

- On-demand MRU: We combine physics-based component degradation and failure models with component and structure sensing and monitoring solutions to provide on-demand maintenance and repair. And the utilization of 3DP/additive manufacturing technology enables on-site repair and upgrades.

- Co-simulation design testing: Hitachi has developed SimXpand (a registered trademark of Hitachi America, Ltd.), the first co-simulation platform developed to test large-scale, complex, system-level designs across industries. SimXpand applies innovative process automation and high-performance computing cloud technology to ease and speed the coordinated use of multiple, heterogeneous simulation applications. The platform requires fewer manual inputs from users, which dramatically elevates the design team’s ability to tangibly and materially drive value for the business.

End-To-End Manufacturing Value Chain Solutions

Hitachi America R&D has 30 years of proven experience in product design, development, manufacturing process technology advancement and production-line problem-solving with industrial organizations. Our end-to-end manufacturing value chain solutions help manufacturers optimize processes, save money, and improve the value and quality of their products, to the benefit of all.